PRODUCTS

Hard Carbon Anode Material

Hard Carbon Anode Material

Introduction

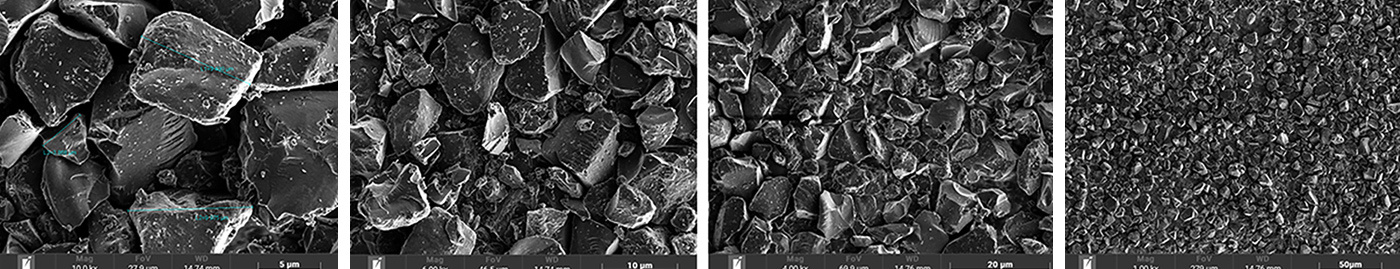

Hard carbon is a hard carbon anode material with dual characteristics of biomass and resin. It uses unique biomass refining technology and advanced preparation processes to obtain bio-based resin precursors, and then prepares hard carbon suitable for lithium-ion batteries and sodium-ion batteries. Carbon anode material. Product features: Wide source of precursors, high consistency, in line with the concept of carbon neutrality; High compaction density; High performance; Black powder, uniform color, no agglomerations and no impurities.

Specification

| Index | Unit | SQNHC-001 | SQNHC-002 | SQNHC-003 |

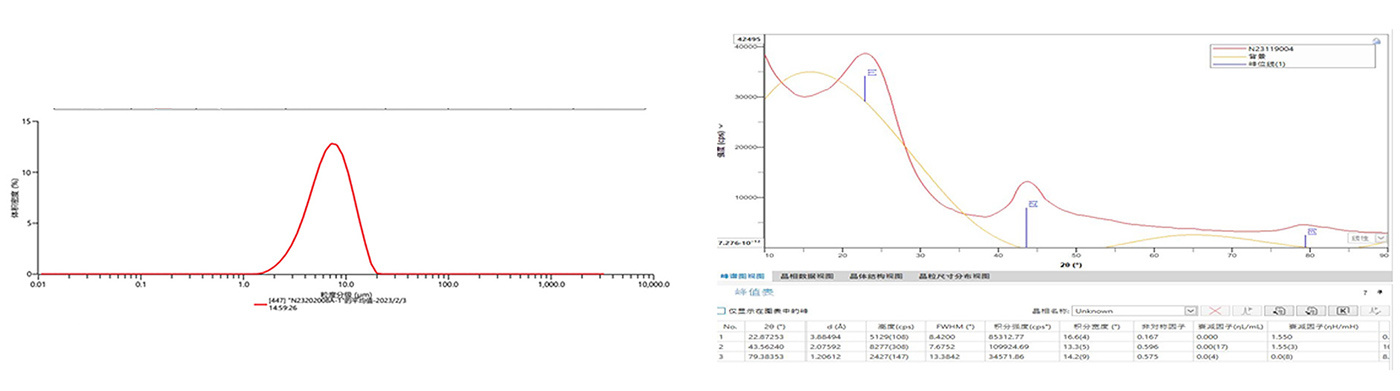

| Average Particle Size Dv50 | Um | 4-7 | 4-7 | 4-7 |

| Specific Surface Area SSA | M2/g | ≤5 | ≤5 | ≤5 |

| Ash | % | ≤0.5 | ≤0.3 | ≤0.1 |

| Vibration Density | G/cm3 | 0.93±0.2 | 0.93±0.2 | 0.93±0.2 |

| Compacted Density | G/cm3 | 1.05±0.05 | 1.05±0.05 | 1.05±0.05 |

| Specific Volume (Above 0V) | MAh/g | 290±5 | 320±5 | 350±5 |

| First Coulombic Efficiency | % | ≥91 | ≥92 | ≥92 |

| Testing Items | Unit | Model | Batch | Test Results | ||||

| Dv(10) | Dv(50) | Dv(90) | Dv(100) | |||||

| Granularity | μm | SQ-NHC001 | N23202008A-1 | 3.637.01 | 7.01 | 12.1 | 18.7 | |

Features

High consistency of the precursor: using biomass as raw material, using unique refining technology and resinization process, a hard carbon precursor with dual characteristics of biomass and resin is obtained;

High compacted density: 5-10% higher than conventional biomass hard carbon;

High cost performance: the precursor has a high carbon yield (above 40%);

There is a lot of room for performance improvement: the precursor can be molecularly designed and modified.

Half Cell Test Recommendations

Slurry ratio: 96 (hard carbon): 1.5 (CMC): 1.5 (SBR): 1 (SP);

Mixing process: 300rpm-10min; 400rpm-20min; 600rpm-30min;

Drying: 90℃ 30-40min;

Surface loading capacity: 12mm diameter disc, about 3-3.5mg of active substance;

Electrolyte: 1.5M NaPF6 in EC/DEC/EMC=1/2/2(V);

Diaphragm: fiberglass (GF/A);

Charging and discharging: leave the battery for 8 hours;

Discharge CC (30mA/g, constant current discharge to 0V at about 0.1C) - CV (0V - constant voltage discharge to 0.01mA), let stand for 10 minutes;

Charging CC (30mA/g about 0.1C - constant current charging to 1.5V/2.5V).

Your Contact Information

CONTACT US

Tel:+8613969029659

Email:stefanie@shengquan.com

WhatsApp:+8613969029659

Add.:Shengquan Industrial Park, Zhangqiu District,Jinan City, Shandong Province, China

Copyright : Jinan Shengquan Group Share-Holding Co., Ltd. Powered by : 300.cn jinan2 Seo Business License